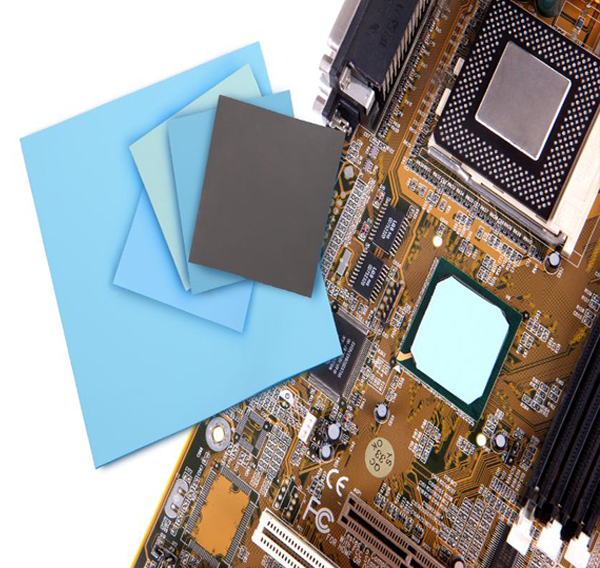

Thermal Pad

The heat conductive filler gasket is made of silicone or non silicone resin as the matrix and filled with heat conductive particles. The thermal conductivity can range from 1 W / MK to 12 W / MK and maintain good elasticity.

The heat conductive filler gasket is made of silicone or non silicone resin as the matrix and filled with heat conductive particles. The thermal conductivity can range from 1 W / MK to 12 W / MK and maintain good elasticity. It can be used to cover the uneven or irregular device surface, fully fill the gap between the heating device and the radiator or metal shell, and make the heat transfer to the radiator more effectively, so as to improve the operation efficiency and service life of the device.

The heat conducting shim is self-adhesive and does not need back glue. For some special use needs, single-sided or double-sided non stick products are also provided for easy operation.

Product features

▪ A variety of thermal conductivity can be selected

▪ Self adhesive or single-sided adhesive

▪ RoHS compliant

▪ Color or size can be customized

▪ TGP series provides conventional hardness products to reduce contact thermal resistance during use

▪ TGP C series provides a higher price performance scheme

▪ TGP s series provides heat conductive gaskets with ultra-low hardness, which can be used under compression of more than 50% without excessive stress.

▪ All series of products can be provided with glass fiber reinforcement (suffix f) and single-sided adhesive treatment (suffix DC1)

Typical application

▪ Chassis or related cooling module

▪ LED lighting

▪ Memory module

▪ Mainframe and small office network equipment

▪ Large storage device

▪ Power Supply

▪ Automotive electronic equipment

▪ Communication equipment

▪ radio set

Technical Specification

|

Performance |

TGP100 |

TGP150 |

TGP200 |

TGP300 |

TGP300S |

TGP300C |

TGP 400 |

TGP500 |

TGP700 |

TGP900 |

TGP1200 |

Test Method |

|

|

Physical |

Density (g/cc) |

2.2 |

2.5 |

2.6 |

3.1 |

3.0 |

2.7 |

3.1 |

3.1 |

3.2 |

3.1 |

3.3 |

ASTM D792 |

|

Thickness (mm) |

0.25-5.0 |

0.5-5.0 |

0.25-5.0 |

0.5-5.0 |

1-5 |

ASTM D374 |

|||||||

|

Hardness (shore 00) |

40 |

10 |

40 |

ASTM D2240 |

|||||||||

|

Thermal |

Thermal Conductivity(W/m.k) |

1.0 |

1.5 |

2.0 |

3.0 |

3.0 |

3.0 |

4.0 |

5.0 |

7 |

9 |

12 |

ASTM D5470 |

|

Operation Temp.(℃) |

-55-200 |

∕ |

|||||||||||

|

Electronic |

Breakdown Voltage (v/mm) |

8000 |

1000 |

8000 |

300 |

ASTM D149 |

|||||||

|

Volume Resistance (Ohm-cm) |

>1013 |

|

ASTM D257 |

||||||||||

|

Dielectric Constant @1MHz |

5.8 |

5.8 |

6.0 |

6.0 |

3.8 |

16.3 |

4.2 |

7.9 |

9.8 |

12.8 |

16.5 |

ASTM D150 |

|

|

Regulatory |

Flaming Rate |

V-0 |

UL94 |

||||||||||

|

RoHS |

Compliance |

∕ |

|||||||||||

|

Shelf Life(Month) |

12 |

∕ |

|||||||||||

188-2226-7107

TIANJIN BROTHERS TECHNOLOGY CO., LTD.

Tel: 18822267107

Email:gavin.ma@brothers-tech.com

PRODUCTS

PRODUCTS